LAMP RESTORATION & REPAIR

For all collectors there is always the question of whether or not to clean a lamp and if so to what extent to clean it. Then there is the question of restoration and repair. Many lamps are found with broken, missing or the wrong parts, many are found bent or dented, many are found corroded or rusted. If a lamp is missing a part or parts there is little question that they should be replaced if available, the same is true of wrong parts found on a lamp. Some damaged parts are repairable and some are not. Many bends and dents can be carefully removed. Rusted and corroded lamps can be made to look better but never llike new.

The aluminum bonnet shown below is an example of what can be done in the arena of dent removal. The dents in this safety lamp bonnet were removed by working them out from the inside with homemade tools designed for that express purpose. Aluminum is more difficult to work with than steel, brass or copper.

Badly dented font and base of a T.R. Jones oilwick cap lamp. This dent appears at one

of the worst possible places to repair, a rolled edge and the point where the base is soldered to the side of the font..

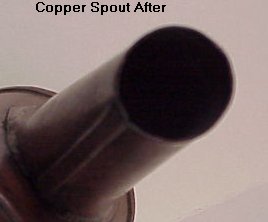

The damage to the end of these copper and brass oilwick lamp spouts was repaired by reforming the end on a round steel rod held in a vise The rod is just slightly smaller in diameter than the interior of the spout.When the rod is inserted it makes a round pattern against which the dents can be tapped out with a plastic hammer. It is always better to make your tools so that they can be secured in a vise so that you have both hands free to work the lamp.

Brass Spout Before

Brass Spout After

On oilwick cap lamps the easiest dents to remove are those found on the ends of the spout because of their accessibility, dents further down the spout and in the font are more difficult to reach. The Brass Felix Lamp below shows what can be done with this type of dent. While dents can be removed gouges and deep scratches in the metal cannot be removed.

Even lamps that are extrensively dented can be restored to a condition that would allow the collector to unashamedly display the piece in their collection.. An example of this is this rare brass screw lid oilwick shown below, while extensively damaged it showed enough promise to warrant restoration.

Shown below are the tools that were used to repair and restore all the lamps seen above, the majority are homemade.

The most important thing to remember when working on a lamp is to take your time, work slowly and methodically to push dents out. Do not expect them to pop right out, they must be worked slowly because once pushed out too far they are next to impossible to fix since the metal has been stretched.

The same lamp with the dent removed and turned 180 degrees.

Before After Before After

This lamp had the lid threads soldered on at an odd angle and the hook had been partially peeled away from where it should be soldered to the font, as well as being bent into too large a loop to be properly attached to a miner's cap. The threads needed to be removed and re-soldered straight and the hook re-bent properly and re-soldered to the font. The result is a much better looking lamp.

This rare oilwick was very rusty, had many small dings and dents, had damage to the threads for the lid and was missing the lid. I was able to clean most of the rust off with very little pitting, remove the dents and dings, repair the threads and find an original period alloy lid to fit perfectly. While many collectors might have passed on this lamp it was well worth the effort to restore.

After

After

Before

Before